Introduction to Copper Nickel Alloy

Release time:

2025-03-14

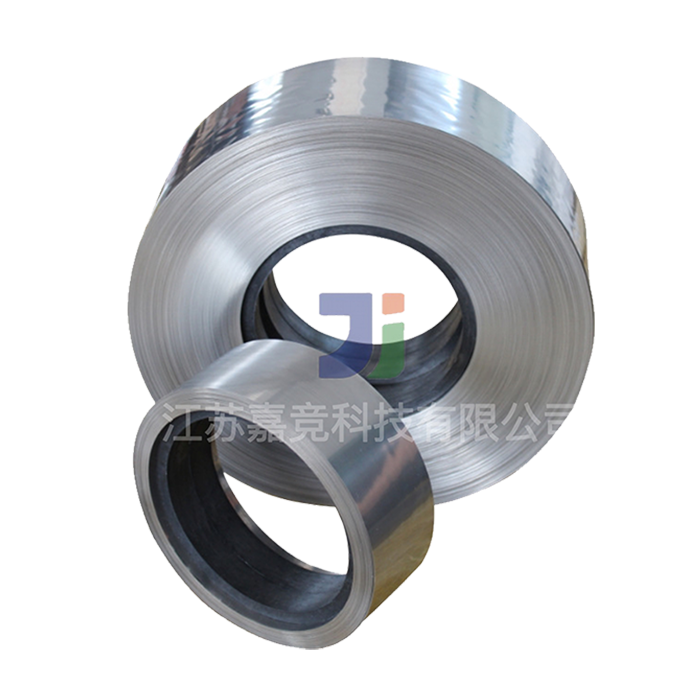

Copper nickel alloy, consisting of copper Cu and nickel Ni, appears silver white with a metallic luster, hence the name white copper.

Copper nickel alloy, consisting of copper Cu and nickel Ni, appears silver white with a metallic luster, hence the name white copper. An alloy is a substance composed of a metallic element and one or more other elements (metallic or non-metallic) fused together to form a material with velocity characteristics. The most basic and independent substances that make up an alloy are called components, abbreviated as elements. In the vast majority of cases, the components are the elements that make up the alloy. But there are also those that use compounds as components, provided that the compounds do not decompose or undergo any chemical reactions within the scope of study. According to the number of components, it can be divided into binary alloys, ternary alloys, or multicomponent alloys. For example, simple brass is a binary alloy composed of copper and zinc elements; Hard aluminum is a ternary alloy composed of three elements: aluminum, copper, and magnesium.

Copper and nickel can infinitely dissolve in each other, forming a continuous solid solution, that is, regardless of their proportion, they remain as alpha single-phase alloys. When nickel is melted into red copper D200 with a content exceeding 16%, the resulting alloy color becomes relatively white like silver. The higher the nickel content, the whiter the color. However, as long as the nickel content does not exceed 70%, the yellow color of copper can be seen with the naked eye. Moreover, the nickel content in white copper is usually 25%. White copper is the elegant name for copper nickel alloy, with a density between copper and nickel of 8.9-8.88.

Identification method

The method to distinguish between white copper and Tibetan silver or Miao silver is that, under normal proportions, the latter two are white and closer to silver in terms of color. However, under modern craftsmanship, aluminum white copper is on par with Tibetan silver and Miao silver in color, even whiter, but with higher hardness and lighter weight. There is no custom of using pure white copper or even aluminum white copper in the Tibetan silver and Miao silver regions. It is known that only some merchants use it to manufacture new wiping molds and non handheld (especially magical instruments and accessories) materials.

characteristic

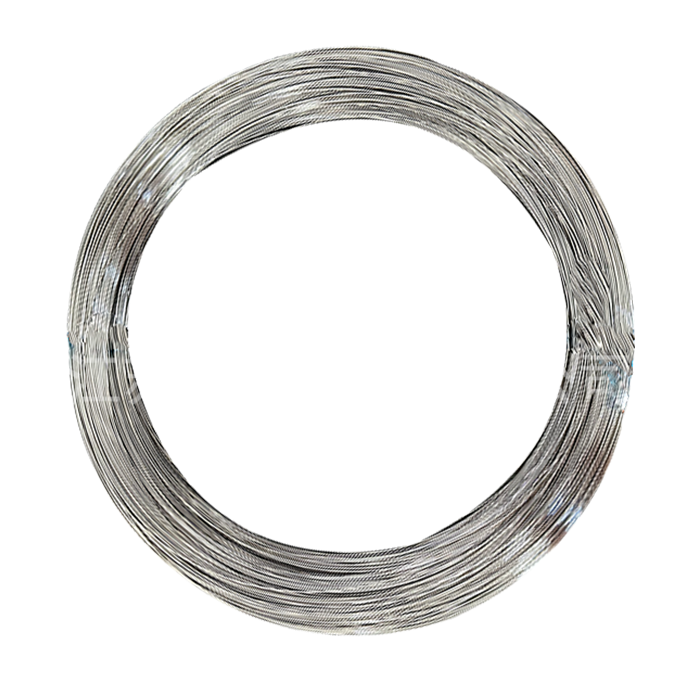

Adding nickel to pure copper can significantly improve strength, corrosion resistance, hardness, resistance, and thermoelectric properties, and reduce the temperature coefficient of electrical resistivity. Therefore, white copper has exceptionally good mechanical and physical properties compared to other copper alloys, with good ductility, high hardness, beautiful color, corrosion resistance and deep drawing performance. It is widely used in shipbuilding, petrochemicals, electrical appliances, instruments, medical machinery, daily necessities, handicrafts and other fields, and is also an important resistor and thermocouple alloy. The disadvantage of white copper is that it mainly adds elements - nickel is a scarce strategic material and is relatively expensive.

purpose

In copper alloys, white copper is widely used as a corrosion-resistant structural component in industries such as shipbuilding, petroleum, chemical, construction, power, precision instruments, medical equipment, and musical instrument manufacturing due to its excellent corrosion resistance and ease of shaping, processing, and welding. Some white copper also has special electrical properties, which can be used to make resistance elements, thermocouple materials, and compensation wires. Non industrial white copper is mainly used to make decorative crafts. [1]