Products

GH4033

Classification:

Product Properties

● Other name: GH4033,ЭП 437 БГ,ХН 77 ТЮР● Origin: Danyang, Jiangsu, ChinaProduct Description

Product Description

● Alloy category: high temperature alloy

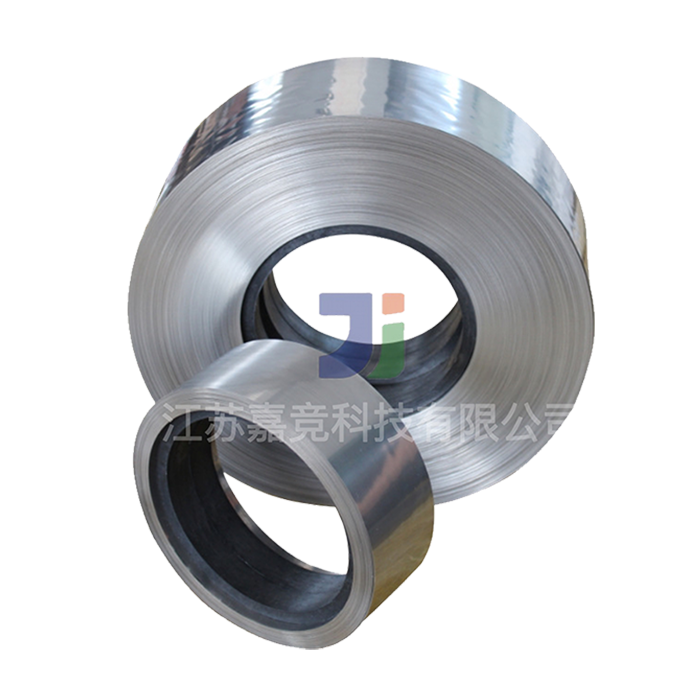

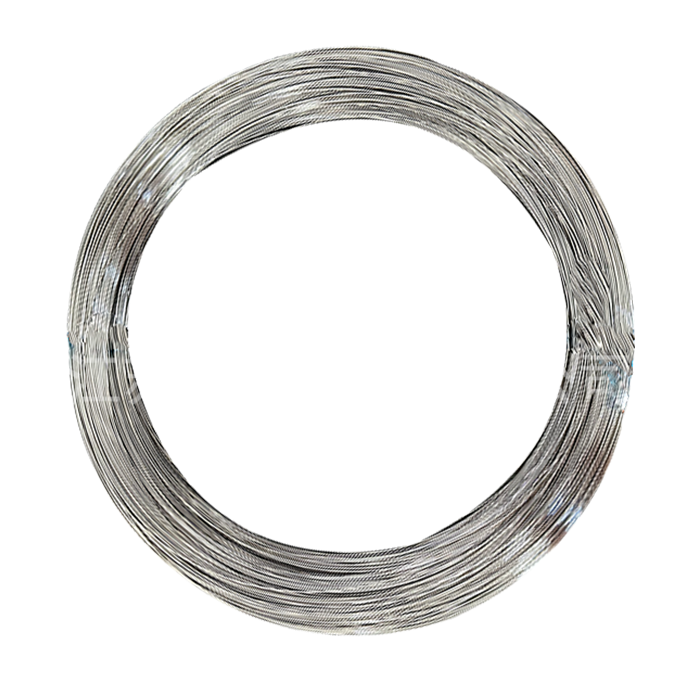

● Base material shape: wire/strip/bar/pipe/plate

● Application areas: aerospace, petrochemical, energy field

Product Description and Application

GH4033 is a Ni-Cr-based precipitation hardening deformation high temperature alloy, to add aluminum, titanium elements to form a precipitation strengthening phase, the use temperature is less than 700 degrees C. The alloy has sufficient high temperature strength at 700 ℃ ~ 750 ℃ and good oxidation resistance below 900 ℃. The cold and hot workability of the alloy is good. It is suitable for making turbine blades working below 750 ℃ and turbine disks working below 700 ℃. The main products are hot-rolled and forged bars, cold-drawn bars, cold-rolled plates, cold-drawn wires, forged round cakes, turbine blades and discs (rings), etc.

GH4033 has been used in the production of aero-engine turbine blades, turbine discs and other high-temperature bearing components.

GH4033 has a large tendency to form uneven grains and coarse grains during hot rolling and forging, and is prone to produce coarse grain waste products. In addition, the production process should be strictly controlled to avoid the phenomenon of tensile plasticity at 700°C.

Ingredient content of GH4033

| Element | Ni | Fe | Cu | Cr | C | Si | Mn | S | P | Al | Ti | Pb | Nb | Co | Ce | As | B | Sb | Sn | Bi |

| GH4033 | Allowance | ≤1.0% | / | 19%~22% | 0.03%~0.08% | ≤ 0.65% | ≤0.40%-0.035% | ≤ 0.007% | ≤ 0.015% | 0.60%~1.00% | 2.4%~2.8% | ≤ 0.001% | / | / | ≤0.01% | ≤ 0.0025% | ≤ 0.01% | ≤ 0.0025% | ≤ 0.0012% | ≤ 0.001% |

Key words:

GH4033

Recommend Products

Welcome to leave a message for consultation