Products

Inconel718

Classification:

Product Properties

● Other names: UNS N07718,GH4169● Origin: Danyang, Jiangsu, ChinaProduct Description

Product Description

● Alloy category: corrosion resistant alloy

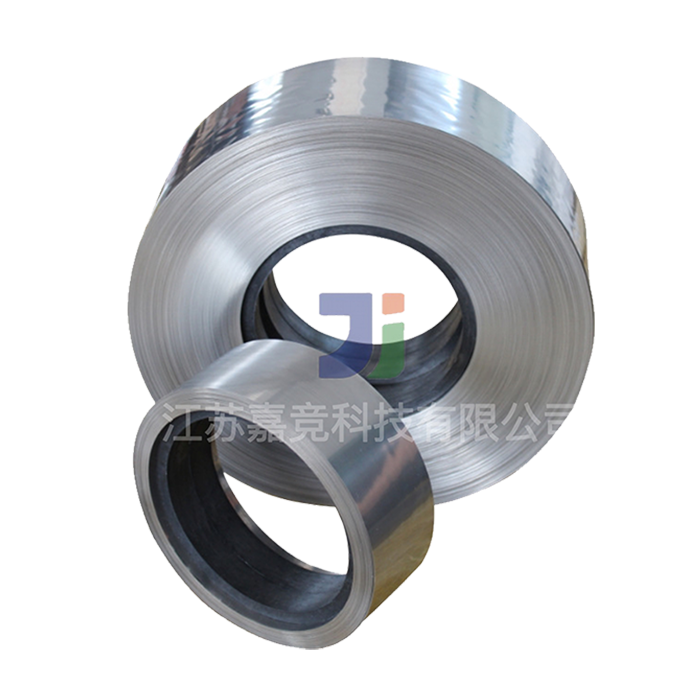

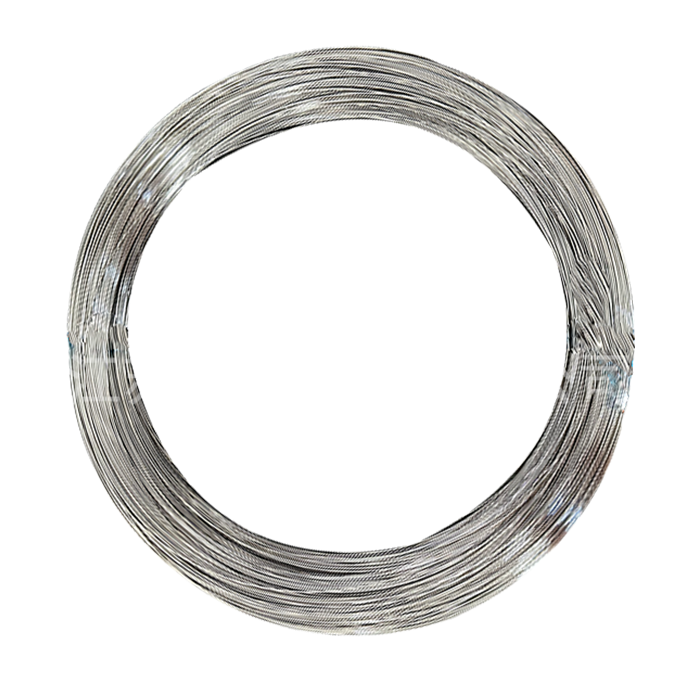

● Base material shape: spindle/strip/straight strip

● Application areas: aerospace, petrochemical, marine, energy field, industrial field, automotive field

Product Description and Application

Inconel 718 is a Fe-Ni-Cr-based precipitation hardening deformation high temperature alloy, long-term use temperature range -253~650 ℃, short-term use temperature at 800 ℃, below 650 ℃ has high strength, good toughness and oxidation resistance in high and low temperature environment. As well as good processing performance and welding performance and long-term organizational stability.

It is used for making rings, blades, fasteners and structural parts in aviation, aerospace and petrochemical industry, and making various parts used in petrochemical industry. It can be mass-produced and has good usability. When the alloy is remelted in vacuum, helium cooling process can be used, which can effectively reduce the segregation of niobium elements, and the use of spray forming process to produce ring parts can reduce the cost and cycle, and the use of superplastic forming can expand the production range. It is suitable for making rings, blades, fasteners and structural parts in aviation, aerospace and petrochemical industry.

Ingredient content of Inconel 718

| Element | Ni | Fe | Cu | Cr | C | Si | Mn | S | P | Al | Ti | Mo | Nb | Co |

| Inconel 718 | 50.0%~55.0% | Allowance | ≤0.30% | 17.0%~21.0% | ≤ 0.08% | ≤ 0.35% | ≤ 0.35% | ≤ 0.015% | ≤ 0.02%-0.015% | 0.2%~0.8% | 0.65%~1.15% | 2.8%~3.3% | 4.75%~5.50% | ≤1.0% |

Key words:

Inconel718

Recommend Products

Welcome to leave a message for consultation