Products

GH4169(INCONEL ALLOY 718/N07718)

Classification:

Product Properties

● Other names: Inconel 718,UNS NO7718,W.Nr. 2.4668,NiCr19Fe19Nb5● Origin: Danyang, Jiangsu, ChinaProduct Description

Product Description

● Alloy category: high temperature alloy

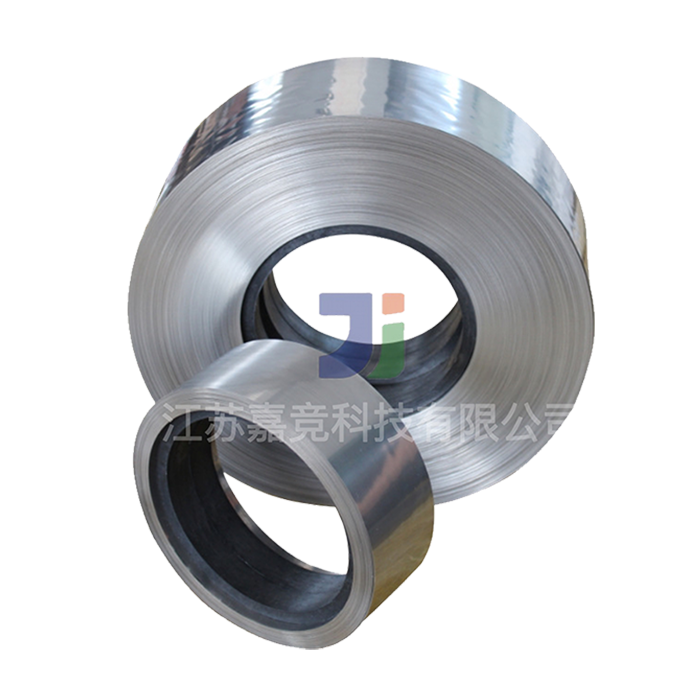

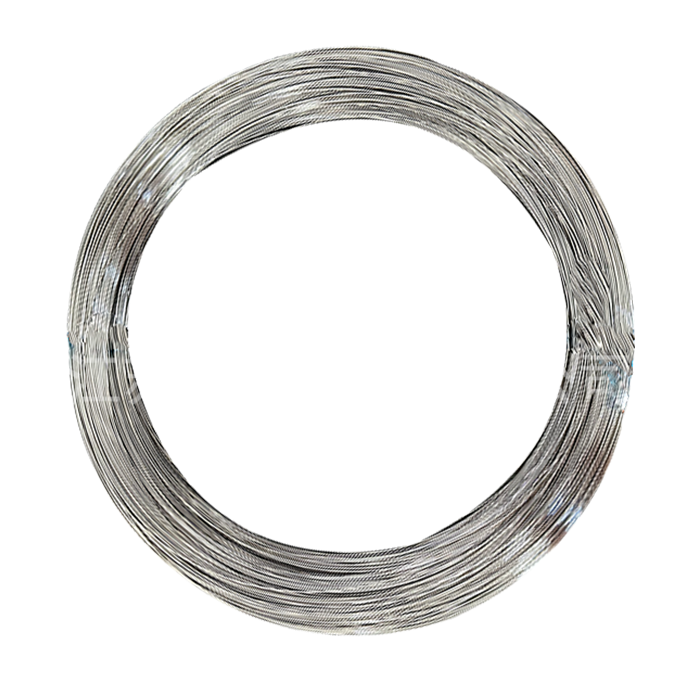

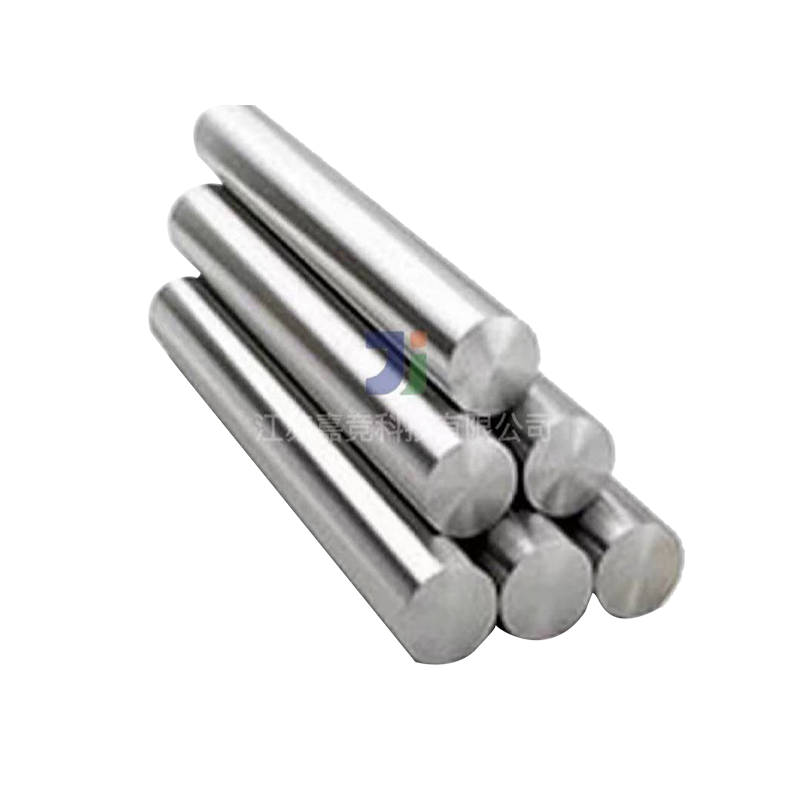

● Base material shape: wire/strip/bar/pipe/plate

● Application areas: aerospace, petrochemical, military fields

Product Description and Application

GH4169 is a Ni-Cr-Fe-based precipitation hardening deformation high temperature alloy, long-term use temperature range -253 ℃ ~ 650 ℃, short-term use temperature up to 800 ℃. The alloy has high strength below 650 ℃, good fatigue resistance, radiation resistance, oxidation resistance and corrosion resistance, as well as good processing performance, welding performance and long-term organizational stability. It is suitable for making turbine disks, rings, blades, shafts, fasteners and elastic elements, plate structural parts, casings, etc. in aviation, aerospace, nuclear energy and petrochemical industries.

Alloys are divided into two categories: ordinary and high-quality. The carbon, niobium, sulfur and gas contents of high-quality GH4169 alloy are more strictly controlled and are mainly used to manufacture various rotating parts. From the manufacturing process, it is divided into three categories: standard, high strength and direct aging. Among them, high strength and direct aging are used for high-quality GH4169 alloy forgings. The thermal deformation temperature is reduced, the average grain size of forgings is refined in turn, and the strength is increased in turn, it can meet the application requirements of different rotating parts in aero-engines.

Ingredient content of GH4169

| Element | Ni | Fe | Cu | Cr | C | Si | Mn | S | Al | Ti | Mo | Nb | Co |

| GH4169 | 50%~55% | Allowance | ≤0.30% | 17~21% | ≤ 0.08% | ≤ 0.35% | ≤ 0.35% | ≤ 0.015% | 0.20~0.80% | 0.65~1.15% | 2.80~3.30% | 4.75~5.50% | ≤1.0% |

Key words:

GH4169(INCONEL ALLOY 718/N07718)

Recommend Products

Welcome to leave a message for consultation