Products

GH4080A(NIMONIC ALLOY 80A/N07080)

Classification:

Product Properties

● Other names: GH4080A,Nimonic80A● Origin: Danyang, Jiangsu, ChinaProduct Description

Product Description

● Alloy category: high temperature alloy

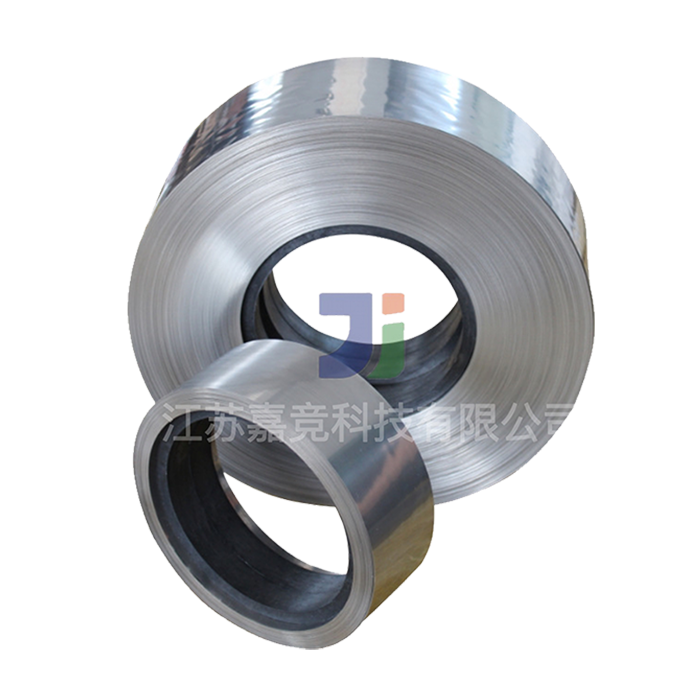

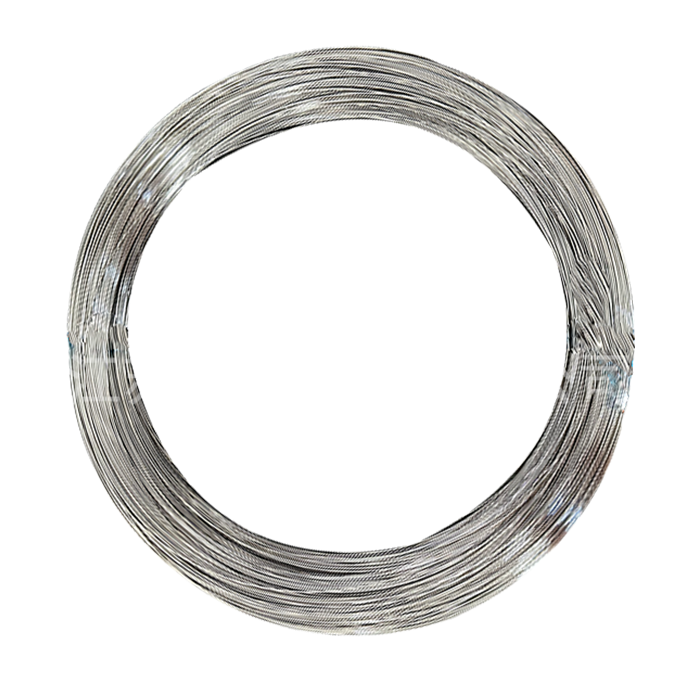

● Base material shape: wire/strip/bar/pipe/plate

● Application areas: sailing ships, aerospace, automotive field

Product Description and Application

GH4080A is a Ni-Cr-based precipitation hardening deformation high temperature alloy, the use temperature is less than 800 degrees C. The alloy is mainly based on the addition of aluminum and titanium elements to form a phase precipitation strengthening phase. The alloy has good creep resistance and oxidation resistance in the range of 650 ℃ ~ 850 ℃. The cold and hot workability of the alloy is good. The main products are hot-rolled and forged bars, cold-drawn bars, hot-rolled plates, cold-rolled plates, strips and ring pieces.

GH4080A has been used in the manufacture of aero-engine rotor blades, guide blade supports, sector mounting rings, bolts, blade lock plates and other parts. In addition, it is also used to manufacture fasteners and blades for automobile engines, as well as valves and shafts for trains. In recent years, with the development of ship manufacturing at home and abroad, the alloy is widely used in the manufacture of ship engine valves. After long-term aging at 700 ℃ ~ 850 ℃ for 1000h, no TCP phase was precipitated.

Ingredient content of GH4080A

| Element | Ni | Fe | Cu | Cr | C | Si | Mn | S | P | Al | Ti | Mo | Nb | Co | Bs | Ags | Bis |

| GH4080A | 32.1%-33.6% | ≤ 1.5% | ≤0.2% | 18%~21% | 0.04~0.10% | ≤ 0.80% | ≤0.40% | ≤ 0.015% | ≤0.02% | 1.0%~1.8% | 1.8%~2.7% | / | ≤ 0.002% | ≤ 2.0% | ≤ 0.008% | ≤ 0.0005% | ≤ 0.0001% |

Key words:

GH4080A(NIMONIC ALLOY 80A/N07080)

Recommend Products

Welcome to leave a message for consultation